About Austraplas

About Us

Established in 1995 , AUSTRAPLAS is a dynamic and expanding Australian owned plastic extrusion, injection and rotational moulding company manufacturing to ISO 9001.2015. When you work with Austraplas you can be absolutely certain of our complete focus on accurate, timely and value based solutions to all your plastic products.

Despite the intense competition from overseas suppliers, Austraplas continues to grow; keeping up-to-date with Global technology and now operates from custom designed premises at Cockburn Central, Western Australia.

Austraplas understands that their future is fundamentally linked with complete customer satisfaction and the following key business

aspects –

- We are local and can assist you with design improvements and dramatically improved turnarounds.

- Because we are an Australian manufacturer we can work on smaller batches rather than committing to multiple container loads.

- We can also work with you at the production level on product evolution.

- Finished products that contain ONLY premium quality raw materials.

- The ability to manufacture for the extremes of temperature and UV so unique to the Australian environment.

- Products that are durable and have a superior life span.

- The quality and longevity of the tools that we work with.

What We Do

Austraplas draws from over 40 years of combined industry experience to maximize your productivity and effectiveness in…

Converting concepts to finished products

Design and problem solving support

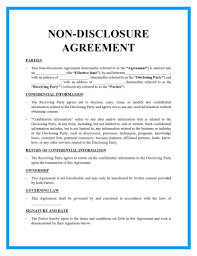

100% design and concept security

UV resistance

Meeting and exceeding budget objectives

Assistance with product and design protection

Additives include…

Glass fibre, Talc and minerals for strength

Master batch colouring and tints

Flame Retardant

Plastics Processed…

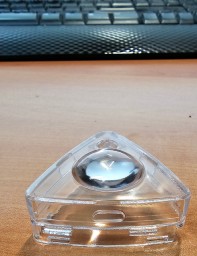

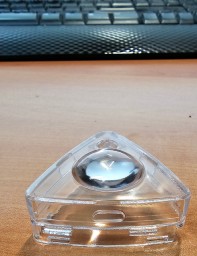

Acrylic (PMMA)

Polyamide (Nylon) 6/66/12 (PA)

High Density Polyethylene (HDPE)

Low Density Polyethylene (LDPE)

Polypropylene (P.P)

Polyvinyl Chloride (P.V.C)

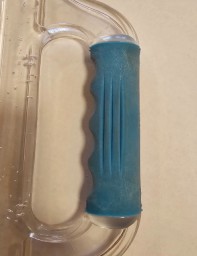

Thermoplastic Polyurethane(T.P.U.R)

Thermoplastic Rubber (T.P.R)

Acrylic Styrene Acrylonitrice (A.S.A)

Ethylene Vinyl Acetate (E.V.A)

Acrylonitrice Butadiene Styrene (A.B.S)

Acrylic (PMMA)

Anti Fowling Marine life and White ant barriers

UV stabilisation or bio-degradability

Glow in the dark

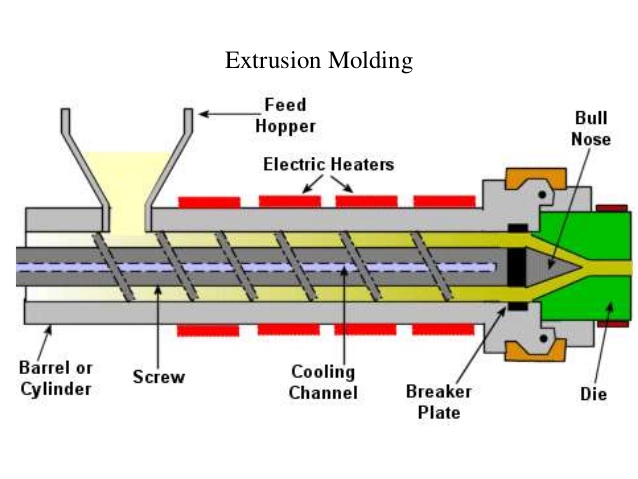

Plastic Extrusion Moulding

Extrusion Moulding is an economical and practical way of mass producing a wide range of linear products. It is ideal for manufacturing rigid and flexible pipes and profiles that are extensively utilized in mining, agriculture, building, medical and domestic markets.

Heated plastic is forced through a die to create a wide range of products such as piping, hoses, plastic profiles and seals. In fact it is almost unlimited in scope and volume produced. Approximately 65% of all plastics pass through an extruder.

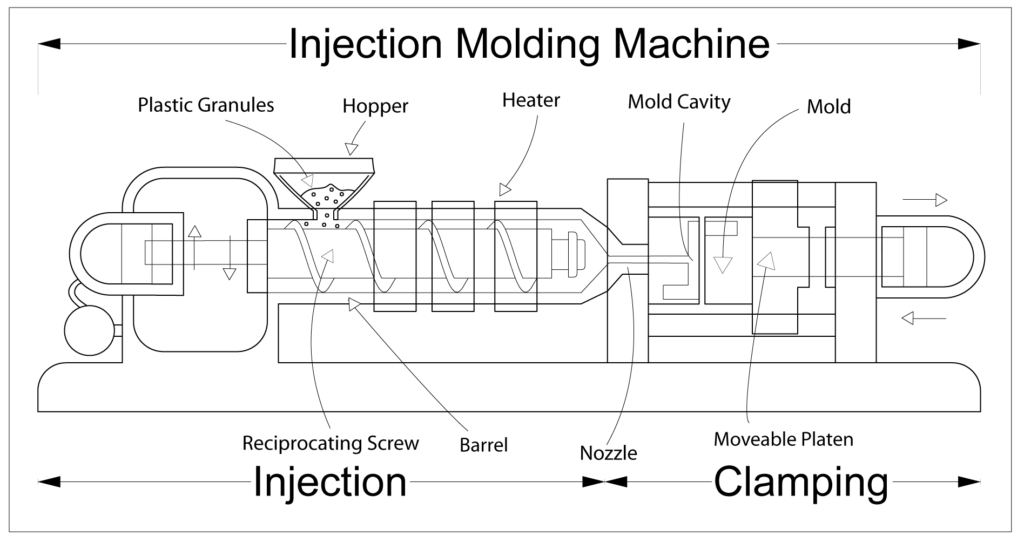

Plastic Injection Moulding

Injection moulding is an extremely versatile and popular form of producing randomly shaped plastic components and products.

With injection moulding, plastic granules are heated and “injected” under pressure into metal moulds, where the molten plastic hardens into a designated shape. The mould then opens and the newly formed part is removed and inspected, ready for shipment or secondary manufacturing operations.

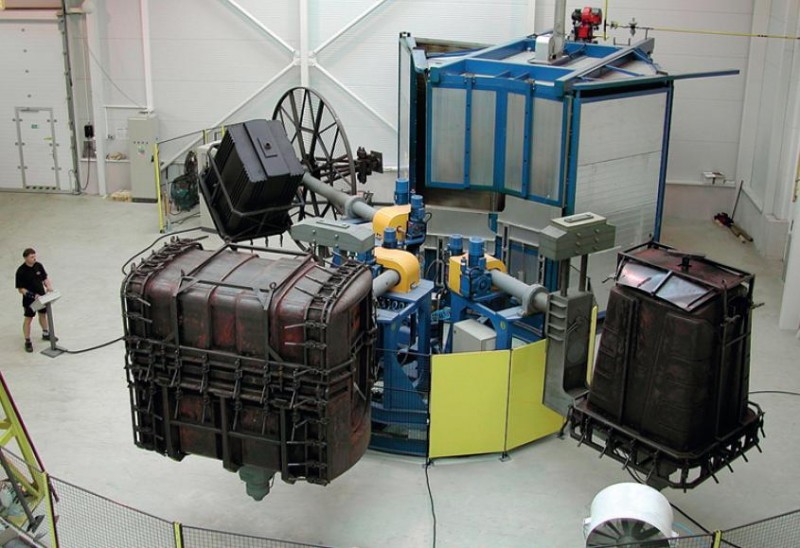

Plastic Rotational Moulding

Rotational molding is best known for the manufacture of tanks but it can also be used to make complex medical products, toys , leisure craft and highly aesthetic point-of-sale products.

The principle of rotational molding of plastics is simple. Basically the process consists of introducing a known amount of plastic in power, granular or viscous liquid form into a hollow, shell-like mold The mold is rotated and/or rocked about two principal axes at relativley low speeds as it is heated so that the plastic enclosed in the mold adheresto, and forms a monolithic layer against the mold surface. The mold rotation continues during the cooling phase so that the plastic retains its desired shape as it solidifies. When the plastic is sufficiently rigid the cooling and mold rotation is stopped to allow the removal of the plastic product from the mold.

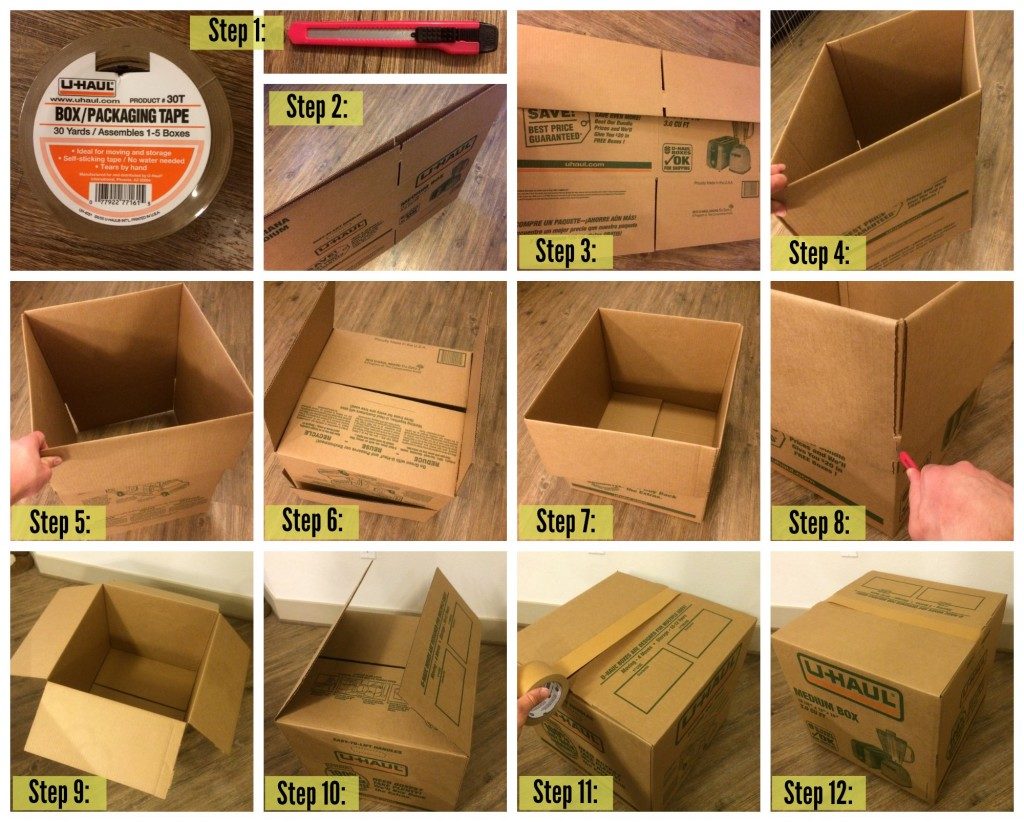

Packaging & Assemble

As a customer focused company Austraplas can assemble product and package ready for market.

Service includes adhesives, labels, cutting and machining, wrapping and packaging into cartons to clients standard.